- Rust removing chemical in the concentrated product.

- Low-foam, specially formulated to remove heavy contamination from rust and light oils.

- Function of preparing metal surfaces for subsequent painting.

Derust

Description

Immersion System

The below shown simple set up of multi-tank dip system will economically de-rust parts of the system.

Directions For Use

Remove solid impurities by using a rag or cloth. By using Brush 10% ~30% of DEV VCI Rust Remover on the entire surface to be derusted. Alternatively, we can also dip. Apply few coats for all surfaces where rust is seen, allow to react, the brown and red colored oxides will dissolve into the solution, additional action by wire brushing will remove the rust faster. Once bare metal is exposed, Apply neutralizing DEV VCI W-Shield+ concentrate.

Properties

- Quick action on contaminated surface, accelerating the removal of iron oxides and peel-able layers.

- Product easy to use, requiring no special equipment.

Features & Benefits

- Gives a fine layer of protection while removing heavy rust.

- Does not etch the bare metal excessively post removal of rust/corrosion.

- For further treatment like painting, de-rusted & neutralized surface will be in good condition.

Rust inhibitor In Singapore

Handling, Storage & Packaging

- Store away from heat, flame or sparks.

- Do not reuse empty containers.

- Protect from harsh weather. Do not have direct contact with skin & wash with plenty of water if situation encountered.

Physical & Chemical Data

| Ideal Working Temperature | Ambient |

| рH | 1.7 |

| Color | Colorless |

| Density at 20°C | 1.391 g/cm3 |

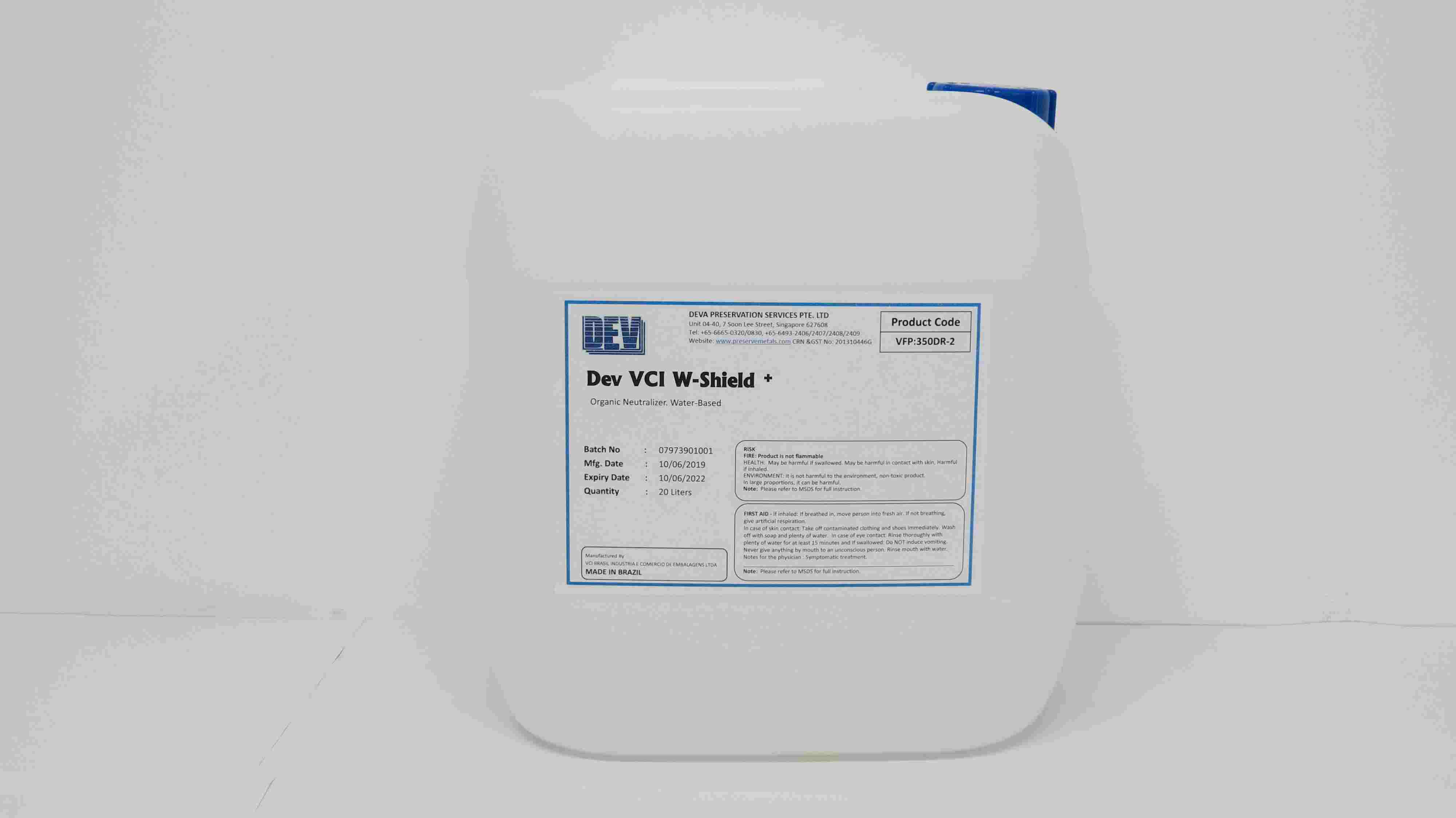

Description

Water-based organic neutralizer that converts acidic residues to natural and forms a protective film on treated surfaces.

Immersion System

The below shown simple set up of multi-tank dip system will economically de-rust parts of the system.

Directions For Use

By using Brush 10% of DEV VCI W-Shield on the entire surface to be neutralized. Alternatively, we can also dip. Apply minimum 2 coats for all surfaces. 100% to be covered and fully changed to neutral pH.

Properties

Neutralizes residual acids from prior processes. Forms an almost unnoticeable thin protective film able to affix stabilizing auto-repairable, anti-corrosive surface.

Features & Benefits

- Gives fine layer of protection while neutralizing the acidic solution.

- Does not cause metal to flash rust.

- Surface will be prepared for further treatment like painting.

Handling, Storage & Packaging

- Protect from harsh weather DEV VCI W-Shield is a soapy solution.

- If in contact with eyes, wash with plenty of water.

- Do not reuse empty containers. Available in 20L carboy can and 200L barrel.

- Available in 20L carboy/200L barrel.

Physical & Chemical Data

| Apperence | Liquid |

| рH | 9.5 to 11 |

| Color | Transparent |

| Density at 20°C | 1.065 g/cm3 |

| Viscosity at 40°C | 9.57 cSt |